Your Site Title

Blackmer

Blackmer

Sliding Vane Pumps

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, push rods, and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers.

As the rotor revolves, fluid flows into the area between the vanes (pumping cambers) when they pass the suction port. This fluid is transported around the pump casing until the discharge port is reached. At this point the fluid is squeezed out into the discharge piping.Blackmer

Model Description

- GX Designed for clean, non-corrosive industrial liquids and petroleum products.

- X Designed for clean, non-corrosive industrial liquids and petroleum products.

- HXL Designed for high volume transfer of non-corrosive liquids ranging in viscosity from thin solvents to heavy oils and molasses.

- ML Ideal for handling everything from thin non-lubricating solvents to highly viscous liquids or abrasive slurries.

- MVP & SMVP Blackmer has combined our proven sliding vane design with a seal-less magnetic coupling to meet the growing need for zero shaft leakage when handling expensive, hazardous or hard to seal fluids.

- P-Series Intended for clean, non-corrosive industrial liquids and petroleum products.

- NP Blackmer NP pumps are specifically designed to offer maximum versatility for handling a wide variety of clean non-corrosive liquids.

- SNP Blackmer SNP pumps are typically used in handling a variety of corrosive or caustic fluids.

- XL Designed for use in refineries, lube oil plants and general industry for processing, filling and transfer applications.

- XLW Designed to handle liquids with suspended abrasive particles, such as oxide primers, inks, paints and adhesives.

- TX A transport pump for clean, lubricating liquid petroleum products.

- TXV A transport pump well suited for high temperature and high viscosity applications.

- ATX A lightweight aluminum transport pump good for a wide range of light fluid applications.

- STX Well suited for loading and unloading corrosive and non-corrosive fluids.

- TransMax A transport pump supporting a wide range of fluids; good for loading and unloading applications.

- LGL Designed for maximum performance and reliability under the most severe service conditions.

- SGL Delivers reliable, highly efficient performance in conditions ranging from low temperatures to high pressure.

- CRL A more durable pump, capable of handling higher working pressures on liquid CO2 service.

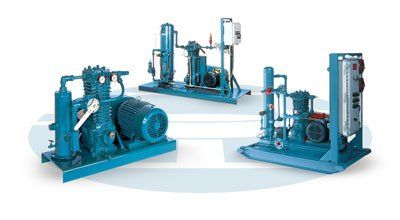

Reciprocating Gas Compressors

The single stage, reciprocating compressors create a low-pressure area in the pumping chamber when the piston moves from the highest point of the stroke to the lowest point. Gaseous product (at a higher pressure in the tank) moves into the pumping chamber. This volume of gas is then displaced when the piston moves to the top of the stroke. Equipped with high efficiency valves, ductile iron pistons, self-adjusting piston rod seals and other robust features, these compressors are designed to provide maximum performance and reliability under the most severe service conditions.

Follow Us

Monday – Friday: 8am-5pm

Weekends: By Appointment

R.A. Ross NE Inc.

Headquarters

10280 Brecksville Rd.

Brecksville, OH 44141

Phone: 440-546-1190

Toll Free: 800-678-4581

Fax: 440-546-1188

Website: http://www.rarossne.com

E-mail: rarossne@rarossne.com

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.